|

PART 1

|

Bren Ten Production Modifications

|

PART 2

|

Hogue Plastic And Herrett Wood Bren Ten Grips

|

PART 3

|

Bren Ten Boxes, Wood Presentation Cases And Soft Cases

|

PART 4

|

"Miami Viced" Bren Tens

|

PART 5

|

Bren Ten Original Prices And Current Value

|

Bren Ten Production Modifications

One of the interesting, and somewhat frustrating, aspects of the Bren Ten are the various modifications made to the guns over

the course of their production. Because the Brens could be ordered with custom serial numbers it is almost impossible to determine

the chronological order of these changes. Also, while some are obvious improvements to the original design, other changes

appear to be possibly labor saving decisions while others may have been nothing more than mistakes. Here is a list of some

of the items that I am aware of:

Trigger Stop

|

| Triggerstops on SFL and SM. |

Probably one of the most common modifications is the installation of a set-screw style trigger stop. These are installed by

drilling and tapping a small hole through the bottom of the trigger guard just before it meets the frontstrap. Both my SM

and SFL have the trigger stop, but they are not installed in exactly the same location. On my SFL the hole has been drilled

vertically and the top of the set-screw had to be ground down at an angle so the trigger could travel the proper distance.

The hole on the SM was drilled at a slight angle and it sits farther back. Because of this the set-screw did not need to be

ground down. I don't recall ever seeing a Bren without the trigger stop, but none of the guns pictured in the '84 catalog

have this feature. I personally feel that this is a very worthwhile addition as the Bren has one of the best factory triggers

(in both double and single action) of any handgun I have handled. Calling a Bren trigger a factory trigger is a bit misleading

however as every gun was basically handfitted. Either way though, they're a real pleasure to shoot!

Round-Top Slide

|

| Thanks to Peko and Austin for this "roundtop" pic. |

If you look at the exploded-view drawing above you'll notice a milled flat that runs the length of the top of the slide from

just in front of the rear sight to just behind the front sight. On this flat between the ejection port and rear sight is the

roll-stamp, "CAUTION - READ MANUAL." On some Brens however, this flat is missing, though they still have the same

roll-stamp. I have heard of both SM's and MP's with this kind of round-top slide, but I don't know of any Special Forces models

like this. Another interesting note is that the flat on my SFL is cut a little deeper than on my SM making it quite a bit

wider. My guess would be that the omission of this flat was simply a labor-saving decision.

Two-Dot And Three-Dot Brens

|

| Comparrison of 2-dot SFL and 3-dot SM. |

References to "two-dot" versus "three-dot" Brens pertains to the markings in front of the manual safety

on the frame. A "two-dot" Bren has two 1/8" dimples drilled into the frame on both sides of the gun. A small

ball bearing on the back of the manual safety rides between the two detents giving the safety a positive "on" and

"off" position. Additionally, the upper "on" position detent is painted red so that when the safety is

in the down/fire position it is visible to the operator. When the safety is in the up/safe position this red detent is concealed

signifying that the pistol is on safe. A "three-dot" Bren though has another dimple drilled in the frame. If you

were to draw a ray starting at the center axle of the safety and projecting through the top dot the third dot is about another

1/8" out (measured center to center). On these guns it is this third dot that is painted red. I think it is safe to say

that the "two-dot" version is the original form of the safety markings as this is the way the guns are pictured

in both the catalog and owner's manual. As to the reason for the third dot I am still not sure. I had originally thought that

the third dot was drilled and painted because it is easier to see. One rumor I have heard though, was that the third dot was

actually a mistake with some frames being drilled incorrectly. Personally I have no preference of one version over the other.

Even if the "three-dot" was a mistake it looks like it should be there.

Magazines (Dual-Caliber, Pinned Floorplates, Hard Chromed Mags, etc.)

One of the things most people seem to remember about the Bren Ten were issues concerning the magazines. When the topic of

the Bren is brought up there's always someone who goes on about how magazines were basically nonexistant or how they didn't

work. While there is some truth to these stories, for the most part they are highly exagerated. To help straighten out fact

from fiction I asked Bruce Orlowski to explain the Bren Ten magazine situation. Bruce writes:

One of the clever features of the original Bren Ten design was that both 10mm and .45 ACP models utilized the same magazine.

The original dual caliber Bren Ten magazines were manufactured by MEC-GAR of Italy with the first lots arriving at the Huntington

Beach facility in early 1984. The feed lip dimensions for both rounds overlapped, allowing functional reliability in the prototype.

The feeding problems encountered with the 10mm ammunition in early production guns proved to be insurmountable however. Additionally,

after about 400 rounds of the original Norma 10mm ammunition was fired from each magazine, the magazine tubes, which were

not heat treated, would become distorted. Many were bent to the point that they no longer could be inserted into the guns

magazine well. Because of this, Dornaus & Dixon refused payment to the vendor. This necessitated a redesign of the magazines

and the 2nd generation 10mm magazines were born.

The 2nd generation magazines design addressed a number of issues in addition to the feeding and durability problems encountered

with the 10mm ammunition. While the dual caliber magazines were shipped to Dornaus & Dixon as complete assemblies, 2nd generation

magazines came as components that were then assembled at the factory. The new magazine tubes were heat-treated, which negated

the durability problems encountered with the MEC-GAR magazines. The original receiver castings were too short in the grip

frame area due to a vendor error. The resulting loose magazine fit contributed to the feeding problems and cause excessive

wear to the magazine catch which, in turn, could allow a charged magazine to drop from the gun during recoil. Two pins were

added at the factory to the magazine floor plates. They did not come this way from the vendor. This provided a temporary

solution to the loose fit of the original magazines until the existing supply of receiver castings was exhausted and a new

lot could be ordered. This never happened for obvious reasons. All 10mm magazines issued by the factory have these pins. It

should be noted that the 2nd generation magazines and dual caliber magazines utilize different springs and followers. These

parts are not interchangeable!

|

| Bren Ten dedicated 10mm mags, with and without "pins." |

The sheet metal parts were sent out for black oxide (bluing), then shipped back and assembled at the plant. The factory issued

no hard chromed 10mm magazines according to Mike Dixon in a Bren Ten Update. The given reason for this was that the heat-treated

magazines would not take the hard chrome evenly. I believe that the real reason was that delivery considerations precluded

the luxury of providing two different finishes.

|

| Pics of hard chromed MecGar dual caliber mags courtesy of Bruce. |

Early production guns of all models were originally shipped with the dual caliber magazines. My Special Forces Light came

with two from the factory. The MEC-GAR magazines function flawlessly in all .45 ACP Bren Ten variations and were issued only

with these guns and .45 ACP Conversion Kits after the 2nd generation magazines became available. One of each type of magazine

was issued with the later Dual Masters.

After production ceased, large numbers of the dual caliber magazines were left in the factory and these are available to

this date. Additionally, enough components for the 2nd generation magazines were left over at the closing to assemble a large

number of these magazines although much of this inventory was deemed defective at the time. Finally, substantial numbers of

2nd generation components were in the hands of the vendors after the shut down either as returned defective parts or new production

awaiting payment prior to shipment. This probably accounts for most of the so-called counterfeit, or after market magazines

often seen. At one time, Wolff made a small run of replacement springs for the dual caliber magazines but none for the 2nd

generation magazines. Some shooters claim a Browning Hi Power magazine spring can be used as a substitute but I cannot confirm

this.

Slot-Head Sight Adjustment Screws

Yet another little idiosyncrasy that I wasn't even aware of! Apparently the original design of the adjustble sights included

the use of two oposing allen-head screws for windage and two on top for elevation. So, for example, if you wanted to move

your rear sight to the left you would back out the allen-head screw on the left side and tighten the opposing one on the right.

This would move and then lock in place the sight. (This is the same system that is used on the rear sight of my DSA SA-58.)

Problems occured though when these screws would "shoot loose" when shooting the hot Norma ammunition. To rectify

the problem this allen-head system was replaced with a more common single slot-head screw setup similar to that found on Smith

& Wesson and Ruger revolver sights. (Thanks to Bruce and Rob for this information.)

|

| Thanks to Bruce for sending in these pics. |

Old-Style

Notice the two allen-head screws and the pin going through the center of the rear sight in the two views from the top. If

you wanted to raise the sight (for example) you would raise the front allen screw and lower the back. For windage, you would

loosen the side in which you wanted to move the sight and then tighten the opposing side to lock it in place.

|

| Thanks to Bruce for sending in these pics. |

New-Style

The newer system for adjusting windage and elevation is very similar to that used on Smith & Wesson and Ruger revolvers. The

top and right-side screw are click-adjustable and much easier to move. I have never shot a Bren with the allen-screw style

sights, but I've never had a problem with the newer style being "shot out" of adjustment.

Unfinished/Media-Blasted Frame

With the obvious exception of the Military/Police and Special Forces Dark, all Bren frames have brushed stainless flats with

all rounded surfaces media-blasted for a matte grey finish. There is one Bren Ten however, that has a frame that does not

have these brushed flats. One of the previous owners of the gun was convinced that this was purposely done at the factory.

Another has indicated that the frame was not media-blasted, but rather it was a frame that was never finished for whatever

reason. I have never seen the gun firsthand, and even if I had I don't feel that I'm knowledgable enough to tell one way or

the other.

Another interesting point about this particular Bren Ten Standard Model is that it sports six digits following the "83SM"

serial number prefix. As far as I know all Brens with a two-letter model code are then followed by a five digit number. Those

Special Forces Light and Dark pistols that have the full SFL or SFD as part of the prefix are followed by four digits because

of the extra letter. This makes for a alpha-numeric serial number consisting of nine characters total, reguardless of model.

These two factors (the frame finish and serial number) make for interesting conversation and conjecture. Whatever the story

is with this particular pistol, it seems to be a unique occurance.

Hogue Plastic & Herrett Wood Bren Ten Grips

When thinking about the Bren Ten, in just about all its forms, we usually think in terms of black plastic grips. There were

the fancy wood grips made for the Jeff Cooper Initial Issue Commemorative that included Col. Cooper's initials and family

crest engraved in them, but these weren't the only wood grips made for the Bren. Not only that, there were other plastic grips

available besides the standard black ones that came stock on just about all models.

Grips for the Bren Ten pistols were made by two different companies. Hogue made the plastic grips while Herrett made the custom

wood grips.

The Hogue combat grips were made of fiberglass reinforced nylon. They had the had the famous non-slip "pebble pattern" surface

and included a molded Bren Ten "X" medallion. What is truly interesting though, is that in addition to the standard black

panels, Hogue also make white "ivory" grip panels and these are very rare indeed. Both versions originally sold for $20 per

set.

Herrett's custom wood grips also came in two versions. Both wore a high-gloss lacquer finish and included rhodium plated Bren

Ten "X" medallions. One pair though was made from fancy select walnut and was finished smooth while the other was made from

plain walnut and included 20 lines per inch checkering. The Herrett custom wood grips sold for $30 a pair.

|

| Front & back views of the standard black plastic Houge grips and the wood Herrett grips. |

Click here to see a Feb. '85 Gun World subscription ad that includes a Bren Ten SM with Herrett grips.

In addition to producing the smooth and checkered wood grips, Herrett also produced the engraved wood grips for the Jeff Cooper

Initial Issue Commemorative. In addition to the rhodium plated Bren Ten "X" medallions the grips also include Col.

Cooper's crest. Along with the Jeff Cooper wood presentation cases, these good looking wood Bren grips can be found floating

around occassionally.

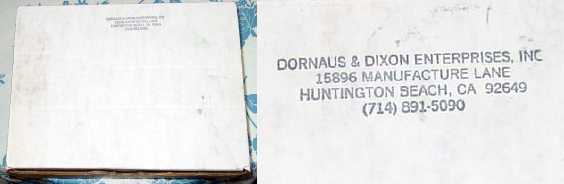

Bren Ten Boxes, Wood Presentation Cases And Soft Cases

The standard box that greeted the proud, new owner of a Bren Ten is underwhelming to say the least. You would think that such

a gun should at the very least come in a custom, form-fitting case with foam inserts to hold and protect such a prestigious

firearm, but this was not the case. In fact, the Bren box is nothing more than a smallish, white cardboard box. Measuring

2-1/2" high, 7-5/8" wide and 10-1/4" long, the box had no interior partitions or any other device to hold the gun in place.

In essence, it was an empty cardboard box.

As far as markings, there really isn't much to speak of. About the only thing you're going to find is a simple rubber stamp

marking (as shown below) and sometimes a model and serial number written in ballpoint pen. That's just about it. Other markings

have been described on the outside of the Bren cardboard box, but these are most likely from dealers or other non-factory

personnel.

|

| Thanks to Bruce for this Bren box pic. |

Neither of my Brens came with the a box, so I ordered two original boxes from Erv at ESF Sales in Florida. Not being very

happy with the prospect of my guns just sliding around the inside (but still wanting everything as original as possible) I

decided to build a simple cardboard insert to hold both the gun and a single extra magazine. Additionally, since I didn't

want to mark on the actual box I made up a lable to place on the insert in which I could record the model and serial number

of the gun. The pictures below show the box with and without the insert. The insert itself is not actually attached to the

box and can be easily removed.

Whereas the standard Bren Ten box was made of simple, white cardboard, there are two special Brens that came encased in something

a little more befitting. The Jeff Cooper Initial Issue Commemorative and the Dual Master both came in custom wood presentation

cases. These cases were made from walnut and measured 3" high, 8-3/8" wide and 13-1/4" long across the front.

The sides of these cases were 9/16" thick with the top and bottom panels measuring 1/4" thick. Hinges and a locking

latch on the front are made of brass. Inside a styrofoam cutout was covered with maroon velour. For the Jeff Cooper gun there

is a cutout for the gun and ten fake gold-plated 10mm cartridges. On the inside of the lid was an engraved metal plaque. (Note

- In the picture below the extra magazine is sitting where the second row of gold plated dummy 10mm cartridges would sit,

and there is no engraved plaque in the lid.) For the Dual Master the extra slide assembly took the place of the ten fake cartridges

and there was no engraved plaque. Also, the Jeff Cooper presentation case has the Gunsite Raven and Col. Cooper's signature

engraved on the cover while the Dual Master case is plain and unadorned in any way. These are both very attractive wood cases

and while Dual Master presentation cases are very seldom encountered, there are a number of Jeff Cooper cases floating around

as the extras were basically dumped after D&D closed their doors.

|

| Thanks again to Bruce for these Cooper Case pics. |

Another highly collectible Bren item is the soft case made for The Marksman Shop. The Marksman Shop commissioned Dornaus

& Dixon to produce the .45 caliber Marksman Special Match pistols, and though there were 250 pistols built there were

only 100 of the soft cases made. Again, the case itself really isn't anything special, but the fact that it's Bren and was

made in very limited numbers makes it a hot item indeed!

|

| Marksman soft case & pistol courtesy of Bruce. |

"Miami Viced" Bren Tens

It's hard to imagine anyone taking a rare and valuable gun (only about 1,500 made and prices starting at around $1,600 now

days) and customizing it in any way. This would obviously ruin the guns value and collectability, right? Well when it comes

to the Bren Ten that's not necessarily true. There is one modification that can be made that, depending on the individual,

may actually increase the desirability of the pistol. That modification is giving the Bren Ten the Miami Vice treatment.

"Miami Vicing" a Bren Ten consists of taking a full-sized Standard Model and hard chroming the pistol's slide to replicate

the finish of the gun used by Sonny Crockett (Don Johnson) on the television series Miami Vice. This is a relatively simple

process and nothing else is required to duplicate the Miami Vice Bren Ten.

|

| Thanks to Bruce for these pics of the Standard Model before the "Miami Vice" treatment. |

Tony was kind enough to share some "before and after" pictures of his Bren Ten. As you can plainly see above, the

gun began life as a basic Standard Model. (As an interesting side note, this is the Bren that did not receive the standard

brushing of the flats on the stainless frame. It also sports a six-digit serial number following the "83SM" prefix

which, as far as I know, is unique.)

|

| Thanks to Tony for these great pics of his "Miami Vice" Bren Ten. |

As you can see, once the transformation is complete you have the pleasure of owning one awesome looking handgun! It's easy

to see why so many people thought the Miami Vice gun was an all-stainless steel pistol.

My own SM will stay in its original condition, but should I ever pick up a second Bren Ten Standard Model I will most definately

be having it "Miami Viced!"

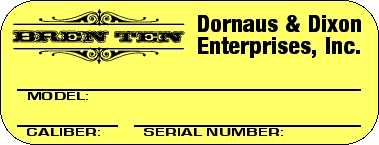

Bren Ten Original Prices And Current Value

It's not to difficult to find the listed retail prices for the various Bren models for back when they were in production.

They would usually mention it in articles and it was also listed in the various gun annuals of the time. I have to say though,

that I was a bit shocked when I found out what one could be ordered for direct from the factory. I probably shouldn't be surprised,

but when you consider what a Bren Ten goes for these days who can blame me for wanting to kick myself when I realized what

I could have got for the same money back in the mid-80's! (This information is taken from one of the original order forms

posted on Jeff's website. Thanks Jeff!)

What is much more difficult, however, is assigning a fair value for a Bren Ten right now, today. I have had a number of people

ask me what a good price would be for a particular Bren with certain accessories (mags, box, manual, etc.). I try to do the

best I can, but there are a number of factors that just make this real hard to do. Of course you can simply purchase one of

the various books on gun values that come out each year, but personally I feel that these really don't take into consideration

the way true Bren Ten collectors feel about the gun.

One thing that makes this hard is that because of the limited number of guns made it isn't like there is a constant number

of guns available all the time. It seems like for a while you can't find a Bren anywhere for any price, and then a few months

down the road a half-dozen or so will pop up. Next, to get a fair price you really need to connect the gun with someone who

knows what it is and is willing to pay what it's really worth. In all honesty the Bren Ten isn't as well known as most other

pistols of its time. So, for example, while you may be trying to sell one at a real good price, you may go without a single

offer on the gun because it's just hard to find people who appreciate what it is and are willing to pay for it (this is where

the internet has come in so handy!). And finally, while the Bren Ten is a great design, it must be admitted that there were

in fact problems with the gun. Therefore when buying a Bren one must carefully consider whether they want to pay the "big

bucks" for a gun that they probably shouldn't shoot all that much, or possibly even at all, due to concerns over potential

metal fatigue and the almost non-existance of spare parts.

Because of these things I am very hesitant to list what a particular Bren Ten is worth. (Besides, I usually pay too much for

my guns in general so I'm probably not the best one to ask anyway!)

|