|

Peregrine Industry's Falcon And Phoenix

Not long after Dornaus & Dixon Enterprises, Inc. closed their doors Richard Voit (of Voit sporting goods fame) purchased the

rights and other materials from the bankruptcy courts and established Peregrine Industries, Inc. In addition to this, Tom

Dornaus was also hired to help in redesigning the Bren to both remedy some of the Bren Ten's flaws as well as "update" the

design and features.

Even though there were going to be some rather significant changes, it was very important that the new gun retain the classic

appearance of the original Bren Ten. For example, while the Falcon does away with the cross-block safety and installs a decocker

in its place (serious design changes), the new company went to the pains of forming a cosmetic "crown-style" bushing into

the muzzle-end of the slide even though the new gun used a different bushing design eliminating the need of the original version.

Also, extensive effort was put into testing the guns to make sure that there would be no breakage problems down the road.

In fact there was a battery of guns that were shot continuiously in an attempt to force potential problems to the surface.

This way the fix could be incorporated into the design before any guns hit the market avoiding costly recalls and repairs.

Peregrine Industries seemed to have learned from Dornaus & Dixon's problems, but the fates were once again stacked against

the Bren. It has been commonly believed that a lack of significant police/military contracts and the resulting lack of funding

forced Peregrine Industries to fold. This was an issue, but it was not the reason for the decision to shelve the Falcon.

The "nail in the coffin" for Peregrine Industries was the fall-out from the imfamous savings and loan scandal. In short,

the S&L scandal prompted many financial institutions to cancel loans to numerous businesses. Being a brand new company with

what was basically an unproven product with no promise of success, Peregrine Industies had their funding pulled. This, not

the lack of police/military contracts, "pulled the plug" on the Falcon.

Contrary to some recent rumors, Richard Voit still retains all rights to the Bren and Falcon. In fact, according to Mr. Voit

all the R&D is done and all that is needed to produce the gun is funding. Personally I would love to see someone like Colt,

Kahr, Kimber, etc. take a close look at the Bren/Falcon design. None of these companies have a successful large frame, double

action pistol in their line-up and the Falcon would fill this hole very well indeed!

Below are three articles covering the Peregrine Falcon. There is a lot of interesting information in these articles, including

a bit of Bren history. Even now when I read it it makes me want to go right out and buy a Falcon! Unfortunately though, as

we all know, the Falcon never "took flight" and so all we can do is read about it.

|

| Thanks to Rob for sending in this pic. |

Originally printed in Guns & Weapons, January/February 1991.

Author: Nigel Milner

Article Title: "Peregrine Falcon"

In mythical times from the ashes would arise a Phoenix. In California they do things differently and from the ashes of the

Bren 10 has arisen a different kind of creature, the Peregrine Falcon. The ill-fated Bren 10 had a short but spectacular life

with approximately 1500 pistols being produced. In 1986 financial problems forced Dornaus and Dixon to close shop and it appeared

to be the end for this fine handgun. It also appeared for a while that the 10mm cartridge would also follow it into oblivion.

However the Colt Delta Elite provided a new home for the cartridge and new models from Smith and Wesson and Springfield Armory

assured its continued existence.

BREN 10 - When introduced in 1984 the Bren 10 was heralded as the perfect combat pistol. Its design was influenced by the

CZ75 and like that pistol allowed the shooter two conditions of readiness. First the pistol could be carried cocked and locked

in Condition One, hammer back and safety on. With the hammer down on a loaded chamber the pistol functioned as a conventional

double action pistol. A long heavy pull on the trigger fired the pistol and subsequent shots were fired single action. The

combination of stainless frame and blued slide provided an attractive and functional appearance. In addition to the conventional

frame mounted safety there was also a unique through-bolt firing pin safety. This was located on the slide just below the

rear sight and when pushed in from the left to right it prevented the hammer from hitting the firing pin. Adding to its distinctive

appearance was the crown style barrel bushing and a hump on the rear of the slide which protected the adjustable sight.

TOO GOOD TO DIE - Richard Voit decided that the Bren 10 was too good an idea to let slip away. He bought the intangible assets

i.e. the design and name from the bankruptcy courts and founded Peregrine Industries Inc. With the assistance of top design

engineers Steve Blair and Tom Dornaus, the next four years were devoted to improving and modifying the Bren 10. A recent visit

to America provided the chance to spend a day at Peregrine's factory and try their new pistol.

Arriving at Long Beach Airport I was met by my guide for the day Shanna Everaert-Robb, Special Services Manager. After braving

the California freeway system we arrived at Peregrine's factory in Huntington Beach. A welcome cup of coffee steadied my nerves

and recharged my caffine levels then we headed for the indoor range. As the only pistols available were pre-production prototype,

function tests only were conducted. As Richard Voit explained later, it would not be fair to report on accuracy etc on what

were basically hand built guns. On the shooting bench lay waiting three virtually identical pistols. The only distinguishing

mark was the calibre designation stamped on the chamber.

The look and fine handling characteristics of the Bren 10 had been preserved. Later I would have the time to do a side by

side comparison but now was time to do some shooting. Each pistol performed flawlessly. The .45 ACP and .40 S&W models were

delightfully easy to control. From a Weaver stance, firing double taps, the sights appeared to come straight back with very

little muzzle rise. The 10mm was a different story but the comfortable grip of the Falcon made even this powerful cartridge

manageable.

The indoor range used rifle bullet traps and as I found out these served to trap unburnt powder grains. After touching off

a 10mm round a glow lit up the area in front of me. The muzzle blast had ignited this loose powder! Visions of headlines reading

"British Gunwriter burns down California factory" flashed past my eyes but a spray bottle of water is kept handy for these

events.

MIX AND MATCH - All Falcons regardless of calibre use the same lower receiver. The .40 S&W and 10mm use exactly the same magazine.

With the slide locked back there is no way to tell which calibre pistol is being handled. My question, as to what would happen

if the wrong magazine was used, was answered when I inadvertently loaded a .40 S&W magazine in the .45 pistol. The slide moved

forward into battery and the cartridge fell straight out the muzzle. Should an attempt be made to use 10mm ammunition in a

.40 S&W the extra length of the cartridge will prevent the pistol from going fully into battery. The only mismatch that will

function is using .40 S&W ammo in a 10mm. Although this is definitely NOT a recommended practice I fired three magazines with

no problems. As a final test a magazine of mixed 10mm and .40 S&W was fired. The Falcon happily digested this varied diet

without a murmur. From the shooters point of view though it was immediately apparent when a 10mm came under the hammer!

TEST TILL IT BREAKS - Tom Dornaus was present during these shooting test and explained the history behind these pistols. Each

had been fired thousands of times. Much of the shooting was done by hand and all employees were involved. They took turns

in loading and shooting. In some tests the pistols were fired until they became too hot to hold. Then they were dunked into

a bucket of water to cool off and the torture continued. Due to the heat levels barrels turned blue. The guns were regularly

stripped and examined. If a part failed or showed signs of wear it was redesigned and retested. To accelerate wear a special

rig was used which clamped the gun securely and only allowed it to recoil straight back, no upward motion was possible. Under

the stresses imparted in this machine any weak links quickly showed up. While I took a break from shooting to man the camera

Shanna showed that she was certainly no slouch with a handgun.

NEW AND IMPROVED - With the shooting session over the time had arrived to take a closer look at the Falcon. For Bren 10 owners

we have some bad news. NO parts of the Falcon are interchangeable with their pistols and this includes magazines. Starting

from the top the sights feature a new twist on the three dot system... square dots. In comparison to round dots the squares

present a larger surface area to the shooters eye and I found lining up the boxes easier in rapid fire. Unlike many adjustable

sights the ones supplied with the Falcon are well protected as was demonstrated when Tom picked up one pistol and hammered

it on the bench. The sight blades disappeared into the protective hump and emerged unscathed. Below the hump the manual through-bolt

firing pin block has gone and has been replaced by a hammer decocking lever. There still is a firing block safety but this

is located inside the slide and prevents any movement by the firing pin unless the trigger is pressed.

On the Bren the thumb safety was a single reversible lever, in the interests of simplicity this has been replaced by an ambidextrous

safety. Also simplified is the recoil system. A full length recoil spring guide is used and the slide velocity has been reduced

to minimize wear and extend the pistols service life. One thing that has not been changed is the method of rifling the barrel.

The Power Seal rifling as developed by Barret Boots Oberineyer is still used. Unlike conventional rifling which is cut at

a ninety degree angle to the bore, the Power Seal rifling is cut at a shallower angle. This sloped surface increases the area

available to guide the bullet and is reported to have a number of beneficial effects. First the bullet is less deformed so

accuracy is improved. As the bullet seals the bore more completely very little gas escapes hence higher velocity.

Many semi-automatic pistols use a barrel bushing system to ensure that the muzzle is returned to a consistent position between

shots. The Bren 10 used a unique Crowned barrel bushing and at first glance it would appear the Falcon has followed suit.

However the crown has been cast on the end of the slide and is there for cosmetic purposes only. A new patented method called

the V-Block system is used. In front of the slide a V is cut. As can be imagined the round barrel has little option but to

fall in the same place time after time. Moving further down the pistol we come to the magazine release. An ingenious design

as in a few seconds, with only a small screwdriver and no need to disassemble the pistol, it can be reversed for left hand

use.

NEW GUN NEW METHODS - Having fired and inspected the Falcon it was time to meet the man behind the gun, Richard Voit. Over

the next couple of hours he explained what he had set out to achieve with the Falcon and some of the company's plans for the

future. His first objective had been to take the original design and improve on it whilst still retaining the distinctive

Bren 10 appearance. Another goal was complete interchangeability of parts. With conventional manufacturing methods where parts

have to be extensively machined this is virtually impossible. Instead a new manufacturing process called Metal Injection Molding

has been used. Similar to plastic molding, a molten metallic mixture is squirted under pressure into a mold. During the curing

process the molded part shrinks by 20%. The result, identical complex parts that require no machining and are accurate to

within 1 thousandth of an inch. Approximately 15 such components are found in the Falcon. At present the technique is limited

to objects about 2 inches square but in the future we may see entire firearms made using this process.

As Southern California has a multitude of high tech companies, skilled in various manufacturing techniques, it was decided

to make use of their expertise. Over a period of nine months companies were selected to manufacture all the component parts.

It would have been quite simple to just present a firm with a set of plans and say build this. However this would not be taking

advantage of the experience the company had to offer. Instead the purpose of each specific part and how it interacted with

other parts was explained. In some cases improvements were suggested by the companies. More importantly it changed their status

from one of merely a subcontractor to that of an active partner.

These parts are then shipped to Peregrines factory where they are assembled, test fired and packaged for shipment. By the

time this article reaches the news stands the first production pistols should have found their way on to the American markets.

Future offerings from Peregrine will almost certainly include a 4 inch barreled version of the Falcon. I had a brief try of

the prototype which worked just as well as its larger brother. Another possibility are conversion kits. Pistols with double

action only, single action only, with or without decockers or any combination of the above are planned, but for sale to Police

and Military only. In the rifle field Peregrine are developing a semi-automatic gas operated rifle in .50 BMG calibre. My

all too brief experience with the Falcon has certainly whetted my appetite and I look forward to giving a production gun a

complete workout. Stay tuned and remember you saw it here first!

The following is the article from the July 1991 Gun World that covers the then new Peregrin Falcon. It's a great read and

though it wasn't a Bren, it was the closest you could get in the early 90's. Unfortunately the Falcon never came to pass.

Originally printed in GUN WORLD, Volume XXXI, Number 11, July 1991.

Author: Eric Kincel

Article Title: "The Falcon 10mm: From The Bren Ten's Ashes Rises A New Auto"

Remember the Bren Ten? Who doesn't? With its demise six years ago, the shooting public wondered if there would ever be another

pistol like it again. Now the hew Flacon is here and it offers all the Bren Ten did - and more.

The Bren Ten started its dramatic but short life with the potential to be the world's best combat automatic pistol. Originally,

the pistol was developed around a cartridge, the 10mm Auto.

The 10mm Auto cartridge, developed in the early Eighties, actually was an old concept. The Italians worked with the 10mm bullet

for use in their service revolver in 1874. The actual size of their bullet was 10.4mm and 10.35mm. At the turn of the century,

Hugh Gabbet-Fairfax in England produced the Mars automatic pistol, which featured a high-powered 10mm bullet. Later, John

Browning even worked with a 9.8mm auto and a 9.65mm cartridge. Browning converted some of his own autos to shoot these creative

rounds. A prototype Hi Power was one and the other, the Colt Model 1911 auto.

Within the last twenty years, .40 Caliber test rounds have been under constant development. In the early Seventies, Whit Collins

designed and developed a cartridge called the .40 G&A. It is a straight-cased cartridge with a length of .886-inch maximum.

The .40 G&A is similar to the .40 S&W, which has a maximum case length of .850-inch. The .40 S&W has proven to be a popular

round for law enforcement.

In the early Eighties, Tom Dornaus and Michael Dixon began developing a .40 caliber cartridge which would achieve high velocity

and maximum stopping power. They created the 10mm Auto with a maximum case length of .992-inch. The next step was to build

a pistol that would shoot this round. The Bren Ten was born.

The Bren Ten actually eveloved from a number of famous pistols, including the CZ-75 and the Browning Hi power. Dornaus and

Dixon added a few of their own designs which now are patented. A number of these features revolutionized the firearm's industry.

Stainless steel was used for the frame and a number of small parts. The slide was carbon steel. Some internal parts were carbon

and tool steel. This mixture made the Bren Ten a two-tone pistol, blued and stainless.

The Bren Ten also featured a double and single action trigger pull that made a lot of shooters happy. The pistol had two safeties,

a frame-mounted safety and a "through-bolt" system which incorporated a safety switch on the rear of the slide. This system

acted as a firing pin block.

The Bren Ten originally came in two calibers, .45ACP and the impressive 10mm Auto. Both calibers fed and functioned flawlessly,

as long as the proper magazine was used. Conversion kits were also available.

In 1986, the Bren Ten production ws ended. Financial difficulties closed the doors of the short-lived company. Just under

fifteen hundred Bren Tens had been built. With the exit of the pistol, the 10mm Auto cartridge was also thought doomed. Norma

Ammunition Compnay, a Swedish corporation, had gone into full production of the 10mm Auto ammuntion. Now, there was a large

amount of ammunition - and no firearm to shoot it.

Shortly after the Bren Ten's demise, Colt - with the help of Dornaus and Dixon - developed and produced the Colt Delta Elite.

The 10mm Auto was still alive. Springfield Armoury and Smith and Wesson soon made their contributions to the renewed life

of the 10mm Auto. Since then, most of the big-name firearms makers developed and produced firearms that chamber the 10mm Auto

cartridge.

Enter Peregrine Industries, Inc., of Huntington Beach, California. Peregrine Industries produces the Falcon, a pistol that

chambers the 10mm Auto cartridge. The Falcon is dramatically similar to the original Bren Ten.

The founder and president of the Peregrine industries is Richard Voit. His grandfather and fater made Voit a respected name

in the sporting goods industry. As a shooting enthusiast, Rishard Voit realized the potential of the Bren Ten and bought the

rights to the firearm, hoping to bring the gun back to life. With that in mind, Voit and Peregrine Industries developed what

they call the Falcon.

Voit wanted the Falcon to improve on the Bren. With the help of top design engineer Steven Blair, he has achieved maximum

accuracy and reliability in the Falcon. Most visual features of the Falcon are similar to the Bren, but there are notable

changes. Voit wanted to preserve the original look of the Bren, including the two-tone look of styling. Other Bren trademarks

were a removeable barrel bushing that resembled a crown, a hump on the rear of the slide that housed the sight and the unique

shape of the grip.

While preserving the styling of the Bren, Voit wanted the Falcon to be safer, straonger, and more accurate and reliable. The

Falcon features a frame-mounted, ambidextrous safety. Located just above the grip, it is operated easily with the hammer either

cocked or uncocked. Pressing the switch upward sets the safety in the on position.

The Falcon also has a firing pin block safety inside the slide. It's a full time firing pin locking device - it's always on

until pressure is applied to the trigger. This is an ideal feature, preventing unwanted firing pin travel, Voit feels.

Another safety device is the slide mounted, hammer decocking lever. It's located on the let rear of the slide, just below

the sight. When the lever is pressed down, the hammer drops to a safe, uncocked position while the firing pin remains in a

locked position.

The recoil system of the Falcon has been improved over the Bren. The original pistol's system wsa much like that of the Colt

1911 auto. It consisted of a recoil spring guide, recoil spring and a spring tube or plug. The Bren also had a buffer built

into the recoil spring guide that acted as a "shock absorber." The system reduced the felt recoil and wear on the pistol.

The Falcon's recoil system has been improved, making the complicated Bren system unnecessary. The Falcon uses a full-length

recoil spring and guide to improve functioning and accuracy. The velocity of the slide has been reduced and the operating

characteristics of the pistol minimize wear on the receiver and moving parts. The system helps tame recoil for quicker recovery

and longer fiream life.

Instead of using a standard style pistol barrel bushing, Peregrine Industries has a new idea that's worked so well it's patented.

It's called the V-Block Accuracy System. A standard barrel bushing keeps close barrel-to-slide fit, but the Falcon developers

considered the snug fit unnecessary. A V has been cut into the forward portion of the Falcon's slide. This allos the barrel

to fall consistantly into place as the slide cycles forward into battery. The cut gives the barrel a memory. This patented

system is ideal for developing the repeated accuracy most shooters seek. The V-Block system should achieve superb accuracy

after a few thousand rounds. Company engineers feel it's an especially sound idea for military and law enforcement.

Voit insisted that the crown-like barrel bushing feature on the Bren be repeated in the Falcon design. Even though the barrel

bushing is not needed, the crown is cast into the end of the slide, giving it the classic Bren Ten look.

In addition to the V-Block Accuracy System, the barrel's Power-Seal rifling greatly enhances the pistol's accuracy. Power-Seal

rifling was developed originally by Barret Obermeyer, considered one of the top barrel makers in the United States. Dornaus

and Dixon found this style of rifling impressive and used it in the Bren. The Falcon also features this unique rifling.

What makes the Power-Seal better than conventional rifling? The ninety degree angle of the conventional rifling allows gases

to escape out the barrel, reducing muzzle velocity. Power-Seal rifling is cut into the barrel at a much reduced angle. This

increases the surface area between the lands and grooves. The projectile has more surface to travel on and achieve a better

seal for maximum muzzle velocity and accuracy.

Dornaus and Dixon advertised that all production Bren Tens would produce a ten-shot group less than one-inch at twenty-five

yards, while that auto ws in production. From my own experience, I know this to be true. The use of Power-Seal rifling in

the Falcon should make it highly accurate.

The Falcon operates on a short recoil system simliar to the 1911 Colt auto and is exactly like the famous CZ-75. Most autoloading

pistols on the market feature a similar or duplicated system.

To enhance accuracy, Perigrine Industries developed and patented the Tri-Square sighting system. It is a three-dot sighting

system, one in the front and two in the rear. Actually, the dots aren't dots but small white squares. I found the old-style

three-dot system easy to use, but this new concept is even more impressive. Lining up the three squares during recovery was

fast and easy when I fired the Falcon.

The rear portion of the slide, besides housing the decocking lever, contains and protects the rear sight assembly. This feature

is another taken from the Bren Ten. A simple design, the sight is rugged, but provides full adjustment for windage and elevation.

The front sight is held in the slide by two well-secured posts.

One feature that wasn't borrowed from the Bren is the magazine release. The release on the Flacon is far superior to the standard

John Browning 1911-style which was featured on the Bren. The Falcon's magazine release isn't really ambidextrous, but it's

reversible. With a standard, small-tipped screwdriver, a shooter can switch the release for either left or right hand.

The test model I examined was a prototype with the serial numner, X 1, Peregrine Industries was reluctant to let the firearm

leave the factory, but I was able to test the Falcon's accuracy with various loads, I did evaluate its function and feel.

As expected, the Falcon functioned and shot wonderfully. The felt recoil resembled the kick of a Model 1076, S&W's newest

10mm Auto. The Falcon actually may kick less than the 1076; it certainly has a more comfortable grip. When comparing the felt

recoil of the Bren Ten and the Falcon, I feel the latter puts up less of a fight.

After shooting a couple of fully loaded ten-round magazine of 10mm Auto ammo, I was able to try the Facon equipped with a

.40 S&W chambered barrel. Shooting the round, I found the Falcon quite easy to control. With the combination of the Tri-Square

sight system and the high-tech recoil assembly, quick recovery in sight line-up was easy to achieve.

The ammunition used for the test was furnished by Pro Load Ammunition of Burbank, California. The 10mm Auto and .40 S&W were

180-grain jacketed hollow points. I've had great luck with cartridges from Pro Load in the past. Ballistically, the Falcon

- with its Power-Seal barrel - should be capable of maximizing the best ammunition on the market.

The Falcon will go through more extensive testing before production models will be produced. The pistol I fired already had

seen thousands of rounds through it. In the Peregrine Industries' vault, I saw thirty different Falcons, all in the process

of being tested. Each had fired on thousand rounds, but that's just the beginning. Each pistol will fire fifty thousand rounds

beforetesting is complete. The Peregrine Industries' staffing will dismantle each firearm periodically during the testing

to check for major wear that might affect performance or safety.

The basic production Falcon will have all the features mentioned here, plus a few extras. Du pont Zytel is the material used

in the Falcon's grip. A beveled magazine well will be standard and the stainless steel magazine will hold ten rounds of 10mm

Auto or .40 S&W. Each pistol will come in the Bren-like two-tone blued and stainless finish.

Peregrine Industries will also offer a few accessories. Hardwood grips will be availableto dress-up the pistol. Featured on

the wood grips is a detailed laser cutting of the manufacturer's logo, a falcon. Also offered will be a three-psitol gun case

carrying the Victoryname, another Peregrine trademark. The soft case is made of ballistic nylon with white material inside

that resembles sheep skin.

The suggested retail price for the Falcon chambered in 10mm Auto or .40 S&W will be $750, I was told. For $725, shooters will

be able to buy a Flacon chambered for the .45 ACP load, a must for die-hard .45 fans.

For more information on the Falcon or any of their other products, write: Peregrine Industries, Inc., Dept. GW, P.O. Box 1310,

Huntington Beach, CA 92647-1310.

With the Falcon, Peregrine Industries has a seeming winner. I can't wait to see what their research and development department

offers in the future. GW

This issue of American Survival Guide has a really good article on Peregrine Industries and their Falcon pistols. What makes

this article particularly interesting is that the author spends a lot of time discussing how Richard Voit became involved

with the Bren Ten and his hopes for both the Bren design and his new firearms manufacturing company, Peregrine Industries.

Originally printed in American Survival Guide, September 1991.

Author: Jim Benson

Article Title: "Peregrine Industries: Falcon Pistol"

The Bren Ten. Although only about 1,500 were ever made, this pistol is something of a legend among the shooting public.

Tom Dornaus and Michael Dixon, principals of the ill-fated Dornaus and Dixon Enterprises, Inc. (DDEI), developed the modern,

hard-hitting 10 millimeter cartridge in the early 1980s. They designed and began producing the unique and sensational double-/single-action

Bren Ten semiautomatic pistol to fire it but were unable, for financial reasons, to go into large-scale production, despite

considerable interest and demand for the first pistol of this type on the American market.

Dornaus and Dixon suspended production of the Bren Ten late in 1985 due to a lack of working capital. DDEI was forced into

Chapter 11 bankruptcy (reorganization) and eventually into Chapter 7 bankruptcy (liquidation). Meanwhile, Colt, Springfield

Armory and other gun makers moved to develop and market 10mm pistols of their own and major ammunition manufacturers began

to produce more and more of this increasingly popular cartridge. Today the 10mm pistol is an accepted and growing part of

the American shooting industry with a number of models available to the public and a number of law enforcement agencies looking

at adoption of guns in this caliber.

In DDEI's search for working capital, Dornaus and Dixon met Richard A. Voit, whose grandfather William J. Voit founded the

W.J. Voit Rubber Company in the 1920s and whose family name is well known and respected in the sporting goods industry.

A life-long firearm enthusiast and successful businessman, Voit was very interested in the Bren Ten. "It was such a unique

product," he said. "I could feel and see the potential." He also saw the challenge of making a success of the Bren Ten project.

He purchased the rights to the Bren Ten and in 1986 formed a new company, the Bren Ten Corporation, to produce and distribute

the Bren Ten. He has since changed the name of the company to Peregrine Industries for a "broader image for marketing considerations,"

and plans on eventually manufacturing and marketing a number of different styles and calibers of guns, the first of which

is the Falcon pistol, which retains the basic design characteristics of the Bren Ten while adding many improvements.

Having successfully run his own sporting goods distribution business which achieved more than $40 million in annual sales

before he sold it, Voit is in a good position to oversee the Falcon venture.

Utilizing the best of Japanese manufacturing techniques, which he is familiar with, Voit is pulling out all the stops to make

the Falcon pistol the highest quality yet 100-percent American-made handgun on the market. He wants the Falcon to be the

most accurate, smooth functioning and reliable pistol in its class as well as "the most comfortable handgun that you can put

in your hand." Another goal is for "total parts interchangeability" among Falcons.

To accomplish this, Peregrine Industries has embarked on an ambitious and expensive, research, design and development program

including extensive testing of prototype Falcons, careful selection and involvement of all vendors associated with the manufacture

of the Falcons, and investment in the very best and highest quality parts manufacturing technologies and processes.

Besides the 10mm caliber, the Falcons are to be offered in .45 ACP and the new .40 S&W calibers, with the first production

guns expected to be made available to the public later this year. In outward appearance, the Falcons will be similar to the

Bren Ten, but they will actually have a number of distinct design improvements which Voit believes will distinguish them as

the best handguns of their type on the market.

In addition to purchasing the rights to the Bren Ten Voit retained the services of DDEI's Tom Dornaus to help create the Falcon.

Voit has also purchased another company, Arcala Engineering, whose former owner, Steven Blair is now an employee of Peregrine

Industries working with Voit and Dornaus on the Falcons and other guns, including a new semiautomatic rifle to be offered

in both .50 BMG and 12.7mm Soviet calibers.

"We are going to be a full-time firearms manufacturer," Voit said. Peregrine will eventually be producing other caliber handguns,

including 9mm and .380 Auto pistols as well as variations of the Falcon, Voit said. The firm is planning a 4-inch barrel

version of the present 5-inch barrel Falcon, as well as models of the Falcon in different finishes and with names like "Combat

Falcon," "Silver Falcon," and "Night Falcon," and accessories for the guns. Double-action-only models are also planned, as

I understand it, and the firm will offer to work closely with individual law enforcement agencies to produce "law enforcement

package" designed specifically for each respective organization's needs.

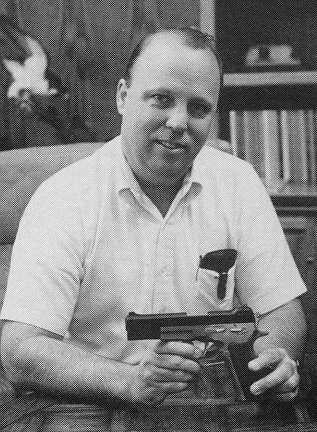

Shown with the prototype Falcon on this issue's cover is the Phoenix, one of only 700 customized guns made by Peregrine and

offered to those former customers of Dornaus and Dixon Enterprises whose orders for Bren Tens were never filled.

The Phoenix is essentially the same gun as the Falcon with the exception of a different finish, engraving on both sides of

the slide ("Phoenix") and on top of the barrel (Peregrine Industries falcon logo) and Pau Ferro smooth wood combat grips.

The limited edition Phoenix is sold with a new Peregrine compact three-gun Victory ballistic nylon carrying case and extra

magazine.

While retaining the Bren Ten's distinctive, shape, grip configuration and two-tone finish, the Falcon offers Peregrine Industries'

patented or patent pending adjustable Tri-Square Sighting System, which utilizes three white squares on the sights which when

properly sighted show up as a solid white line, and Power-Seal Rifling which increases the surface between the lands and grooves

in the barrel and provides a better seal of the projectile as it exits the barrel for maximum velocity and accuracy.

Additionally, the Falcon features the patented V-Block Accuracy System. Instead of the usual barrel bushing for close slide-barrel

fit, a V is cut into the forward portion of the Falcon's slide and the barrel falls into this V each time the gun's action

is cycled and it is readied to fire. A crown-like barrel bushing on the prototype Falcons pictured here and retained from

the design of the Bren Ten, may be done away with on production guns.

The Falcon is designed to function with any commercial 10mm loading and consists of a little over 70 parts. The barrels are

forged steel. The receivers are investment cast stainless steel and the slides are investment cast carbon steel. The grips

are a composite plastic material.

There are three safety mechanisms incorporated in the gun. The ambidextrous thumb safety is moved upward to engage and prevents

both double and single-action trigger functions. A decocking lever located on the left rear of the slide allows the hammer

to be safely dropped on a chamber with a live round in it without the operator touching the trigger. There is also an internal

passive firing pin lock which prevents the gun from firing until the last fraction of trigger movement rearward.

As part of the quality control program in producing the pistol, the magazine shipped with each gun will be fired in that pistol

with a full load of ammunition in it before leaving the factory.

When we visited Peregrine Industries' modern 29,000-square-foot plant and offices facility in Huntington Beach, California,

late in the spring, only prototype Falcons existed and these were undergoing extensive testing. Some pre-production models

were to have at least 50,000 rounds of ammunition run through them before production for commercial sales begins. None of

the pre-production guns were allowed out of the company premises. We were given a tour of the facilities and allowed to test

fire each of the three calibers of prototype Falcon pistol in the company's testing lab.

In the 10mm Falcon we fired Pro Load 180-grain jacketed hollow point ammunition. In the .45 ACP model we fired Hornady 185-grain

JHP ammo, and in the .40 S&W model we used Pro Load 180-grain JHP. All the prototypes had barrel rifling of 1 turn in 16

inches with a right hand twist. We were informed this would likely be the rifling for the .45 ACP barrels but not necessarily

for the 10mm and .40 S&W barrels, as testing was continuing and a decision on this aspect of the Falcon line had not been

reached.

Taking hold of any of these guns - all of which were the same size externally, gives you a feeling of comfort and balance.

Even a shooter like myself with relatively small hands will have no trouble wielding this classic firearm comfortably and

agilely.

Recoil was strongest with the 10mm, as would be expected, but even that recoil seemed moderate and highly manageable. The

trigger pull was light, somewhere around 3-4 pounds, I guessed, and very smooth. Firing into a bullet trap, we could not

test the guns for accuracy, but they all functioned very smoothly and without any hang-ups whatsoever.

Voit expects to begin commercial production of the Falcons shortly after this article is printed, and he is planning for a

"dealer direct" marketing arrangement whereby middlemen are bypassed and the company can have a "24-hour turn-around" in shipping

orders. "We are going to be supporting the dealer, not the mass merchants," Voit said.

In the company's vault, we saw a prototype 4-inch Falcon. We were, for understandable reasons, not allowed to photograph

the gun, but viewing it as well as looking at and handling and firing the pre-production 5-inch models, has got us excited

and eagerly anticipating getting our hands on one of the first production guns for testing and evaluation.

For more information about the Falcon pistols and other Peregrine products, contact Peregrine Industries, Inc., Dept ASG,

7601 Woodwind Drive, P.O. Box 1310, Huntington Beach, CA 92647-1310; phone (714) 847-4700; fax (714) 847-4141.

|

| Richard A. Voit holding one of his Falcon pistols (Sep 91 American Survival Guide). |

While there were quite a few prototype and test guns made, no Peregrine Falcons ever hit the market. Interestingly enough

though, a few of the accessories have found their way into the hands of collectors. One of those was the Peregrine Victory

Case. There is nothing especially unique about the soft case, and in fact it wasn't designed all that well aparently, but

it is a neat little piece of the Peregrine story. Stu sent in a couple of pics of his Peregrine Victory Case, still with the

original tags.

Another interesting piece of Peregrine puzzle is the price sheet that came as part of the dealer packet. Brian sent me a copy

of his original so that we could post it here. Just click on the link below the Victory Case picture to view the copy.

|

| Thanks to Stu for sending in this pic of his Peregrine Victory Case. |

Click here to view the Peregrine Industries 1991 Dealer Wholesale Price List

Triton Cartridge Corporation

A couple years ago rumors started going around that someone was considering bringing back the Bren Ten. The "interested party"

was Fernando Coelho, founder of Triton Cartridge Corporation. Triton Cartridge Corporation had a great reputation for high

velocity handgun ammunition, and its owner was quite familiar with the Bren Ten. In fact, a Bren Marksman Special Match even

graced the opening page of their internet website!

Rumors started popping up that Triton had purchased the rights and was preparing for production. As we now know, the new

"Triton Falcon" never came to be. The story was that Triton, after thoroughly investigating the potential risks versus returns

of taking on such a project, decided that resurrecting the Bren Ten was not in the best financial interests of the company.

As it turns out Triton never did more than make a few "feeler" phone calls. Mr. Voit still owns all rights, patents,

intellectual property, etc. concerning the Bren Ten and Falcon pistols.

The following message was posted by Triton Cartridge Corporation on The Firing Line internet gun forum:

From: TritonCartridge

Date: 02-09-2001

For the past few years, Triton has been considered the reintroduction of the Bren 10. With a project such as the Bren 10,

there were many factors that had to be analyzed thoroughly. These considerations ranged from researching intellectual property,

design concerns, engineering interests, legal costs, and lastly, market viability.

While we have received numerous mailings and phone calls supporting the project, we have determined that it is in the best

interests of our customers and investors to continue focusing on production of the finest ammunition available. Therefore,

Triton Cartridge Corp. regrets to announce that the conclusion of our market research forces us to abandon the Bren 10 project.

Triton would like to thank those who showed continued support for Triton, in both the Ammunition and the Bren 10 arenas. We

value your support and understanding in this decision.

I find it rather interesting that, "...Triton Cartridge Corp. regrets to announce that the conclusion of our market research

forces us to abandon the Bren 10 project," considering there was no "Bren 10 project" to begin with. This was apparently

a no-go from the very beginning, but there's still hope that we will some day see the return of the Bren Ten.

|